Transflective Display combines transmissive backlight with a reflective layer, using ambient light outdoors (slashing power ~30%) and backlit indoors. It achieves high outdoor contrast (e.g., 1000:1 vs. 200:1 on transmissive screens), eliminating glare for clear visibility in varied lighting without manual switching.

How It Works Simply

While a standard smartphone display can consume over 2-3 watts of power at full brightness, a transflective display can slash this by up to 70-80% in daylight by leveraging ambient light. This technology is engineered for reliability in demanding conditions, with operating temperature ranges typically spanning from -30°C to +80°C and a lifespan often exceeding 30,000 to 50,000 hours of continuous use.

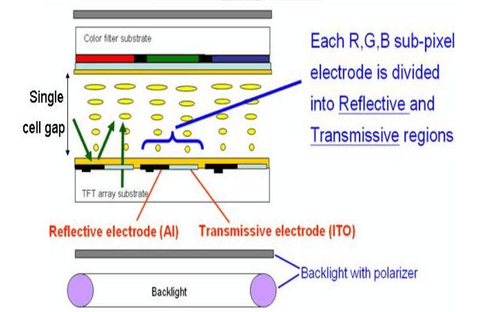

The Core Component: The Semi-Transparent Mirror

At the heart of a transflective TFT LCD is a specialized layer positioned between the liquid crystal cells and the backlight. This isn't just a mirror; it's a partially reflective, partially transparent (transflective) layer. The exact ratio of reflection to transmission is calibrated for the application, often aiming for a 60/40 or 50/50 split to balance readability in both dark and bright settings. This layer is incredibly thin, often measuring less than 0.5 millimeters in thickness, ensuring it doesn't add significant bulk to the display module.

The Two Operational Modes in Detail

This dual-purpose layer enables two distinct ways for the screen to create a visible image:

-

Reflective Mode (for Bright Conditions): In direct sunlight or under bright office lighting (e.g., > 10,000 lux), the backlight can be dimmed or turned off completely. Ambient light hits the screen, passes through the liquid crystal layer, and then bounces off the transflective layer back to your eyes. The liquid crystals, as usual, act as shutters to form the image. This process makes the display behave like a digital piece of paper, becoming clearer and more readable as the external light gets brighter. In this mode, power consumption can drop to a mere 0.1 to 0.5 watts, relying almost entirely on free ambient light.

-

Transmissive Mode (for Low Light): When you are indoors or in a dark environment (e.g., < 100 lux), the backlight is activated. Its light shines forward, passing throughthe transflective layer and the liquid crystals to reach your eyes. The transflective layer is designed to be transparent enough to allow for a bright, vibrant image. While some light (approximately 30-50%) is inherently lost or reflected backwards by this layer, the backlight's intensity is calibrated to compensate, ensuring a clear image in all conditions. Modern transflective TFTs can achieve a typical contrast ratio of 300:1 to 500:1 even in transmissive mode.

The Critical Role of the Front Polarizer

Transflective displays use an anti-glare (AG) treatment on the front polarizer. The AG treatment is often specified by its haze value, typically ranging from 25% to 50%, which defines how much it diffuses the light.

Key Benefit: Sunlight Readability

Where a typical smartphone screen emitting 500 nits of brightness becomes virtually unreadable under direct sunlight exceeding 100,000 lux, a transflective display thrives. By leveraging ambient light, it can achieve an effective perceived brightness equivalent to over 1000 nits without increasing power consumption.

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Physics of Sunlight Visibility

A standard LCD suffers from specular reflection, where light bounces off the glossy surface like a mirror, creating a bright, blinding glare that obscures the image. A transflective display is designed to combat this with two key features:

-

Anti-Glare (AG) Surface: The top polarizer has a matte, etched finish that scatters incoming light. This treatment, with a haze value typically between 25% and 50%, drastically reduces specular reflection by diffusing the light in many directions.

-

Controlled Internal Reflection: The transflective layer is a diffuse reflector. Instead of reflecting a sharp beam, it scatters the incoming ambient light uniformly back through the LCD layer.

Quantifying the Advantage: Contrast Ratio is Key

The difference between the brightest white and the darkest black. In bright light, a standard LCD's contrast ratio can plummet to below 5:1, making details indistinguishable. A transflective display maintains a high contrast ratio, often staying above 20:1 even under 100,000 lux conditions.

Power Efficiency and Operational Readiness

The sunlight readability benefit directly translates into massive power savings and enhanced reliability. For a device powered by a 10,000 mAh battery:

-

With a standard LCD consuming 2.5 watts with the backlight at 100% in sunlight, the device might operate for only 4 hours.

-

With a transflective LCD, the backlight can be turned off, reducing power draw to perhaps 0.5 watts for the logic board only. This can extend operational life to 20 hours or more, a 400% increase.

This reliability is crucial for 24/7 mission-critical applications in outdoor logistics, public transportation, and medical devices used in various lighting conditions. The display's performance remains consistent across an operating temperature range of -30°C to +80°C, ensuring readability from frozen warehouses to hot vehicle dashboards.

Inside: The Reflective Layer

The transflective layer is the defining component of the entire display system, a precision-engineered feature that typically adds a 5% to 15% cost increase compared to a standard transmissive TFT. It is not a simple mirror but a micro-structured optical element, often with a thickness of only 0.2 to 0.5 millimeters, integrated between the backlight unit and the liquid crystal cell. Its primary function is to act as a dynamic light router, intelligently managing the two available light sources: the internal backlight and ambient light. The efficiency of this layer is paramount; a well-designed layer can reflect up to 50% of incoming ambient light while transmitting another 40-45% of the backlight's luminosity, with the remaining 5-10% being absorbed as an inherent system loss.

Situated directly behind the liquid crystal layer, it is the first surface the backlight encounters and the final surface ambient light hits before being reflected. This layer is not uniform; it is often composed of a matrix of millions of microscopic structures or a semi-transparent metallic coating, such as a thin aluminum film deposited with a thickness measured in angstroms (Å). The manufacturing process requires precision etching or deposition techniques to achieve a consistent transmission/reflection (T/R) ratio across the entire display area, with a tolerance of less than ±5% variance.

A 50/50 ratio provides a balanced performance for general use. However, for applications prioritizing sunlight readability, a 60/40 ratio (60% reflection, 40% transmission) is common, sacrificing some indoor brightness for superior outdoor performance. Conversely, a 40/60 ratio might be used for devices primarily used indoors that only occasionally need sunlight visibility. The design choice directly impacts the required backlight strength. A display with a 50% transmissive efficiency will need a backlight that is approximately twice as powerful as a standard LCD's to achieve the same on-screen luminance in transmissive mode, a critical factor in power budget calculations for the device.

Engineers must select materials that maintain dimensional stability across a wide temperature range, typically -40°C to 85°C, to prevent delamination or optical distortion. The surface morphology is engineered to be a diffuse reflector. Instead of acting like a mirror that creates a sharp, distracting reflection of the viewer, it scatters the incoming light. This scattering effect, characterized by a haze value of over 90%, creates a soft, even illumination for the pixels, which is the fundamental reason for the high contrast ratio in bright light. The size and distribution of these microscopic scattering elements are calculated to optimize the viewing cone, often providing a clear image within a 120-degree horizontal and 90-degree vertical viewing angle.

Comparing Reflective & Transmissive

While Transflective LCDs offer a hybrid solution, understanding the fundamental differences between purely Reflective (R-LCD) and Transmissive (T-LCD) technologies provides essential context. A standard smartphone T-LCD might consume over 400 nits of brightness from its backlight, drawing 2-3 watts of power, yet become unreadable outdoors. In contrast, a dedicated R-LCD, consuming just 0.1 watts for its circuitry, remains visible in sunlight but fails in darkness.

The core distinction lies in their fundamental light source. A Transmissive LCD is entirely dependent on its internal backlight, a powerful array of LEDs that can generate 300 to 1000 nits of brightness. This light passes through the liquid crystals and color filters to create an image. In a dark room, this provides a vibrant, high-contrast image, often with a ratio exceeding 1000:1. However, in an ambient light level of 50,000 lux (a typical cloudy day), the backlight's output is overwhelmed. The display's contrast ratio can plummet to below 5:1, rendering it washed out and unreadable. To compensate, users often max out the backlight, which can increase power consumption by 50% or more, draining a 5000 mAh battery in just 4-5 hours instead of the expected 8-10 hours.

It has no backlight whatsoever. Its surface is a mirror-like reflector that bounces ambient light back through the LCD layer. Under bright sunlight of 100,000 lux, this reflected light provides a clear, sharp image with a stable contrast ratio that can remain above 15:1. Its power consumption is minimal, typically less than 0.1 watts, as it only powers the thin film transistors that switch the liquid crystals. This enables devices like e-readers to operate for weeks on a single charge. The critical failure point of an R-LCD occurs when ambient light drops below 50 lux (a dimly lit room).

The performance gap widens when considering color and viewing angles. Traditional monochrome R-LCDs, like those in early calculators, are very effective. However, creating a full-color reflective display presents a significant challenge. The color filters in a standard T-LCD absorb a high percentage of light; in a transmissive display, this is compensated for by a powerful backlight. In a reflective design, the same filters can absorb over 75% of the precious ambient light twice—once on the way in and again on the way out—resulting in a dim, murky color image. Advanced technologies like Kaleido 3 for e-readers have improved color performance, but the color gamut typically remains around 30-40% of the sRGB spectrum, compared to 90-100% for a standard T-LCD. Viewing angles are also narrower for many R-LCDs, with contrast shifting significantly beyond a 45-degree angle.

Common Uses and Examples

Transflective TFT LCDs are not a one-size-fits-all solution; they are a specialized technology engineered for specific, demanding environments where reliability trumps pure entertainment value. Their market penetration is strongest in sectors where display failure is not an option, and where operational conditions can range from pitch black to blinding sunlight within a single work cycle. These displays are commonly found in sizes ranging from compact 1.8-inch diagonal screens for handheld devices to larger 10.4-inch panels for vehicle dashboards, with a typical cost premium of 10-25% over a standard industrial-grade transmissive TFT.

|

|

|

|

|

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor, Marine, and Automotive Systems

On a bright day, sunlight intensity on an open boat can exceed 120,000 lux. A standard display would be useless, forcing the operator to shield the screen with their body or seek shade. A transflective display, however, becomes clearer under these conditions. By turning the backlight down to 20% or lower, it not only remains perfectly readable but also significantly cuts power draw. For a vessel running on a 12V battery system, this can mean the difference between a chartplotter that drains the battery in 6 hours and one that lasts for a 24-hour fishing trip. Similarly, in automotive applications like digital instrument clusters or head-up displays (HUDs), a transflective layer ensures that critical speed and warning information is always visible, even when the sun is low on the horizon, without needing to max out the backlight and generate excessive heat that can reduce LED lifespan from 50,000 hours to under 30,000 hours.

Industrial Control and Measurement Instruments

A technician using a multimeter or an oscilloscope in a bright factory with 1,000 lux overhead lighting needs to read values instantly and accurately. A transflective display on these instruments provides a high-contrast, glare-free screen, reducing the probability of reading errors that could lead to costly downtime or safety incidents. The power savings are equally critical; a handheld thermal camera used for preventive maintenance inspections can operate for a full 8-hour shift on a single charge because its transflective display allows the backlight to be set at 30% instead of 100%. This directly impacts workflow efficiency, eliminating the need for mid-shift charging and reducing the total cost of ownership over the device's 5-7 year operational lifespan.

Medical Devices and Public Information Kiosks

A patient monitor in an operating room must be readable under the bright 500-1000 lux surgical lights and also during lower-light recovery. A transflective TFT ensures the vital signs are always clear without sudden, distracting adjustments to the backlight brightness. For portable medical devices like infusion pumps or monitors used during patient transport, the power efficiency is a matter of operational security, ensuring the device remains active for the entire duration of a 2-hour hospital transfer. In public spaces, ticket vending machines, airport check-in kiosks, and outdoor digital signage use transflective technology to guarantee 24/7 functionality. These systems experience the full range of daily and seasonal lighting variations. The technology ensures information is always accessible, reducing customer frustration and service calls, which can cost an average of $150-200 per visit for a technician.

Pros and Cons Summary

A transflective display typically carries a 10-25% cost premium over an equivalent standard transmissive TFT and may exhibit a 20-30% lower peak brightness in a dark room due to its semi-transmissive layer. However, in mixed or bright light conditions, its advantages become overwhelmingly significant, often leading to a 50-400% extension in battery life and a 100% improvement in usability.

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

The most significant advantage of a transflective display is its unparalleled performance in bright light conditions, which directly enables massive gains in power efficiency. Under direct sunlight exceeding 100,000 lux, where a standard transmissive display becomes unreadable even at maximum power draw, a transflective screen can be perfectly clear with its backlight off. This scenario reduces the display's power consumption from a typical 2.5-3.5 watts to just 0.3-0.5 watts for the driving electronics alone. For a device powered by a 7.4V, 4000mAh battery, this can translate to an operational runtime increase from 6 hours to over 24 hours, a 300% improvement.

However, this outdoor superiority comes with inherent compromises in indoor visual performance and cost structure. The key component, the transflective layer, absorbs and scatters a portion of the backlight. This results in a lower maximum luminance—often around 250-350 nits compared to 450-600 nits for a standard industrial TFT—when both are operating in a dark environment. The colors can appear less saturated, with a color gamut coverage typically around 70-80% of the NTSC standard versus 85-92% for a high-quality transmissive display.

The operational reliability and environmental robustness of transflective TFTs are major pros for industrial and automotive applications. These displays are specifically engineered to perform consistently across a wide temperature range, typically from -30°C to +80°C, and can withstand higher levels of shock and vibration, with specifications often rated for 5-7 Gs of operational vibration. The expected lifespan for the LED backlight in a transflective module is typically 50,000 hours to half-brightness, ensuring a long service life in 24/7 operational systems. This reliability reduces the total cost of ownership over a 5-7 year product lifecycle by minimizing maintenance downtime, which can cost hundreds of dollars per hour in industrial settings.

Read more

Keeping type Hour Meter can realize several feature by providing one start or clear signal, for example Start ,Pause, Resume, Clear

Introduction of serial of outdoor display panel. Displaymodule is your one-stop display module shop.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.